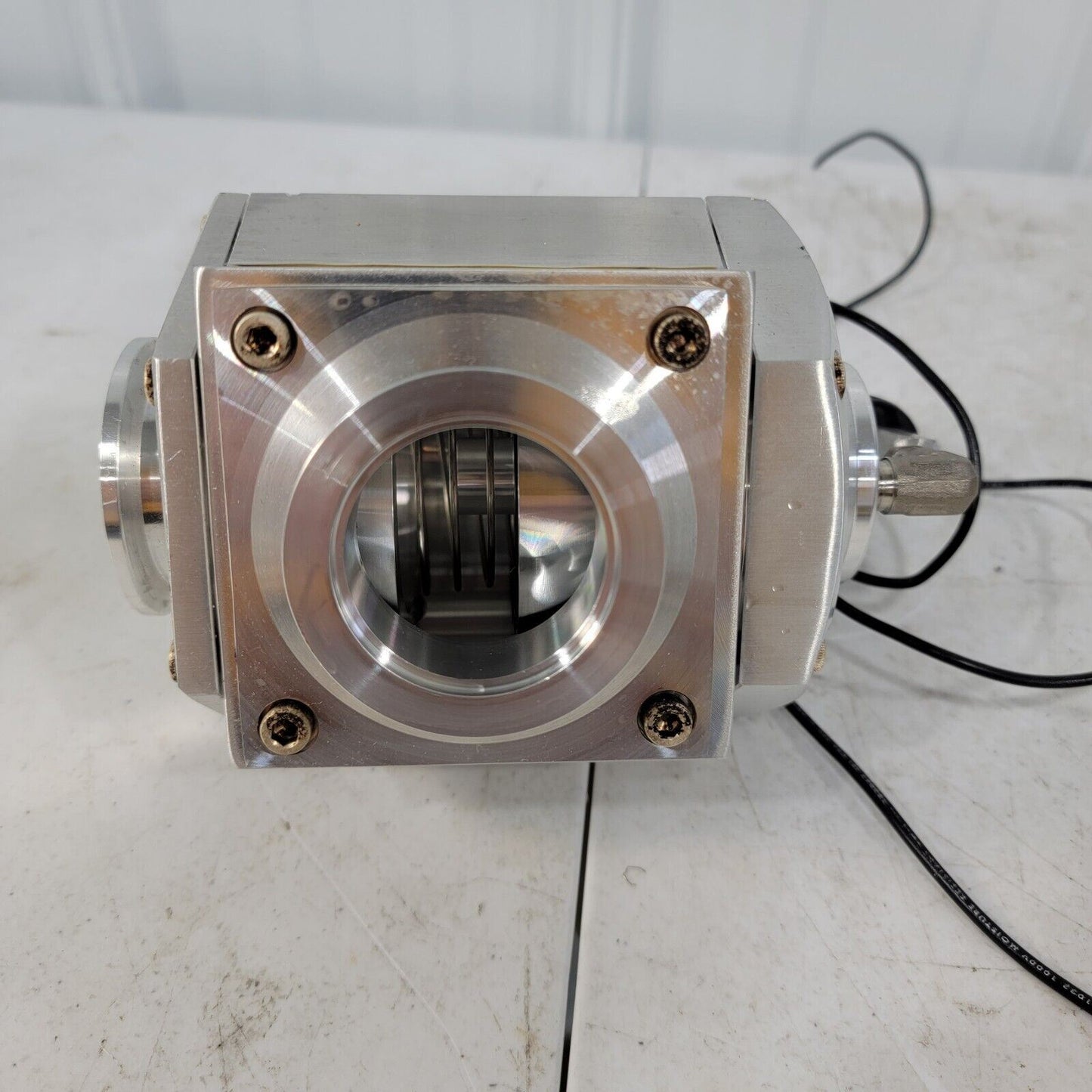

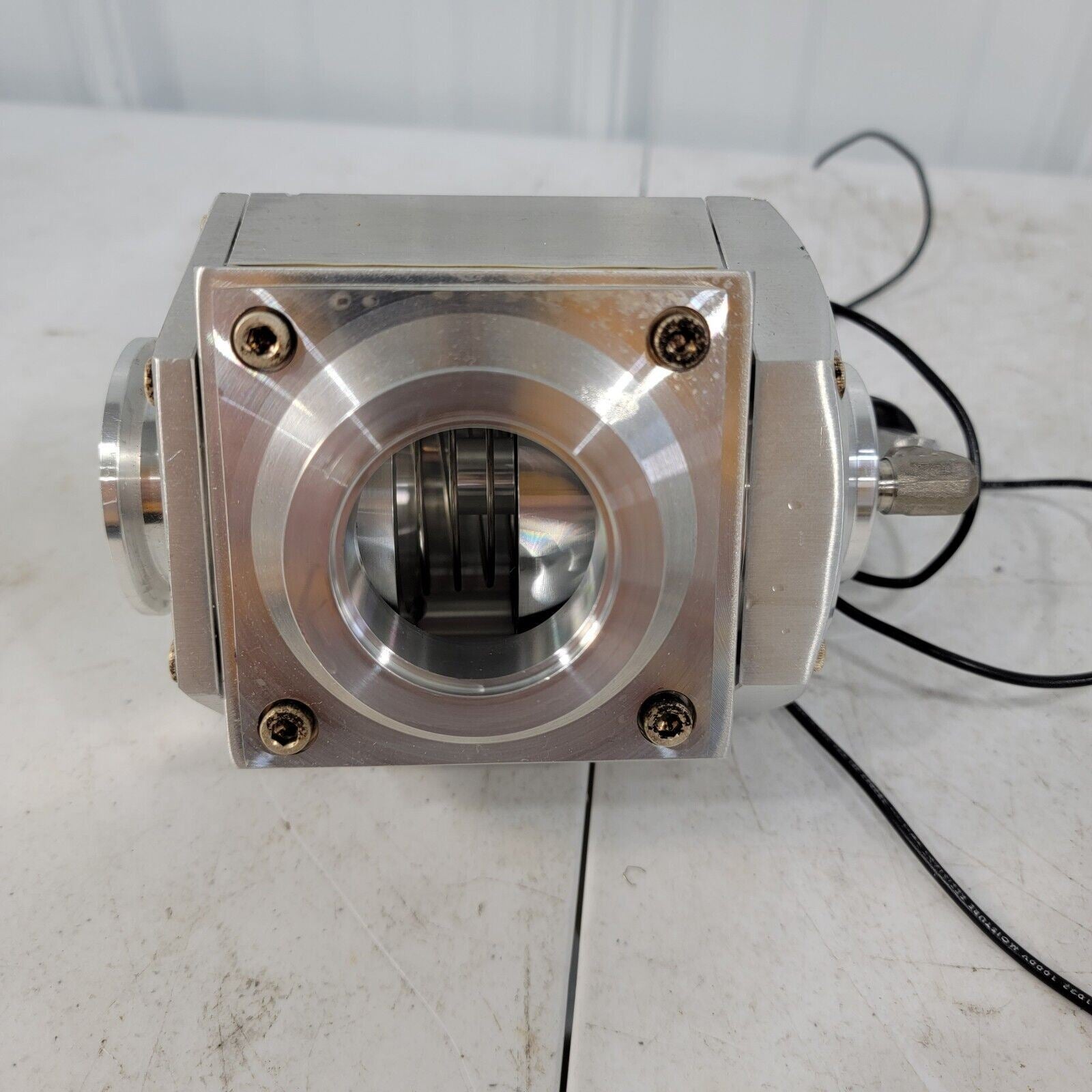

Kurt J. Lesker Anti Suck-Back Vent Valve QF40 KF40 208VAC 60HZ ASVQF40-208A

Kurt J. Lesker Anti Suck-Back Vent Valve QF40 KF40 208VAC 60HZ ASVQF40-208A

Sold out

Couldn't load pickup availability

Kurt J. Lesker Anti Suck-Back Vent Valve QF40 KF40 208VAC 60HZ ASVQF40-208A.

From the manufacturer:

"Auto-Off Safety Vent Valves (KF Flanged)

Our automatic foreline shut-off valve is a safety valve that protects the vacuum system upon power failure by isolating the vacuum system and venting the mechanical pump.

Features

Eliminate time consuming and costly cleanup of dirty vacuum lines, caused by oil backstreaming from the pump

Small orifice in the shut-off valves vents the mechanical pump to atmospheric pressure for easy restart when power resumes

Even when the mechanical pump is equipped with an anti-suckback valve, these valves are recommended because the pump’s integral valve will not vent the pump

Available in a variety of ISO-KF flange sizes, solenoid voltages, and frequencies

How it all works

The automatic foreline shut-off valves (anti suck-back vent valves) are connected in parallel with the mechanical pump’s electrical supply, either at its source or at the pump’s switch. When the electrical power is on, the solenoid valve is held closed, enabling the pump to keep both the shut-off valve’s body and the vacuum system evacuated. Interruption of electrical power to the mechanical pump causes the solenoid valve to open, admitting air into the shut-off valve, causing it to close. The pressure differential between the outside atmosphere and the vacuum system provides the necessary force to maintain the valve in its closed position without the aid of electrical or pneumatic power. With the vacuum system isolated, a series of small orifices admits air into the inlet port of the mechanical pump until it has risen to atmospheric pressure. When the power comes back on, the solenoid closes the pump. The mechanical pump is then restarted, and evacuates the area above the piston until the pressure is lowered to approximately that of the vacuum system. The automatic foreline shut-off valve then reopens, enabling the vacuum system to be pumped at the full speed of the mechanical pump.

Additional features and benefits

Protects vacuum system from oil backstreaming in the event of power failure (to the pump)

Enables quick system restarts

Operates up to 100,000 cycles

No external pressurized gas source required for actuation

Available in a variety of sizes for use with the most common mechanical pumps"

Share